Sloping Block Builders

The Shed House are expert sloping block builders for the Sunshine Coast and surrounding areas. What are the benefits of suspended Steel floor systems for sloping blocks? Steel frames allow engineering for less posts with longer spanning capabilities. Our frames will not rot when exposed to weather. Your frame and posts will always stay true and straight. Our clever engineering allows for fast sloping block build times. Our frames require less brackets at junctions and can cantilever out for suspended decks - talk about an architectural masterpiece!

Check out our 9 step process in more detail below and watch our video!

Quicker - Smarter - Stronger

Step 1 - Design

When constructing your new shed home or granny flat on a sloping site, the design of the floor system is the critical first step. A good floor system design considers a range of factors including footings, posts, bearers, joists and connection details. When working in difficult terrain, an efficient design is critical for construction accuracy and speed to avoid budget blowouts.

Step 2 - Materials

There are a number of methods employed by sloping block builders to construct suspended floor systems, the two most common are:

- Over the top – where timber bearers connect to the posts and the joists run across the top of the bearers and are connected using nails.

- Inline floor systems – utilising steel bearers and joists where the bearer is the nesting channel, enabling the joist to sit within the channel. The benefit of this floor system is its ability to be lower to the ground. Therefore less posts are required. This can result is a faster construction time. This is the method employed by The Shed House.

Step 3 - Soil Conditions

When designing the floor system, we will consider the soil conditions. The soil will bear the load of the building. This is established by completing a soil test within the building envelope. The soil test will tell us what the bearing capacity is. This enables us to complete engineering for the footing details, which are specific to your land.

Step 4 - Footings

The footings are the holes which we auger into the ground to carry the post for the floor system. They are typically 450mm in diameter and the depth is entirely dependent on the soil conditions. Once the holes have been excavated, and the post is positioned, concrete is poured to secure the post.

Chat to one of our friendly sloping block builder consultants today about our building process!

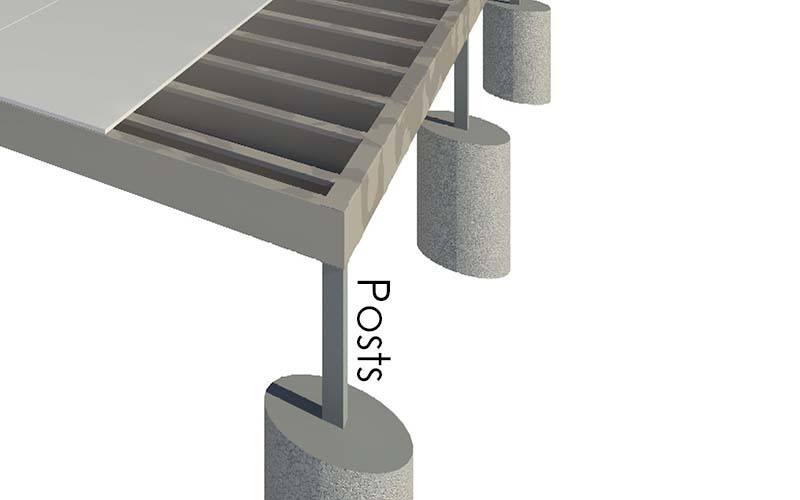

Step 5 - Posts

Floor system posts come in a variety of shapes and forms ranging from hardwood timber, round treated logs, H beams and SHS. The Shed House choose to use SHS which come standard with Duragal coating. This coating protects from the elements, therefore preventing corrosion. SHS is a strong, cost effective option and provides a clean finished product which is above all easy to paint in the colour of your choice.

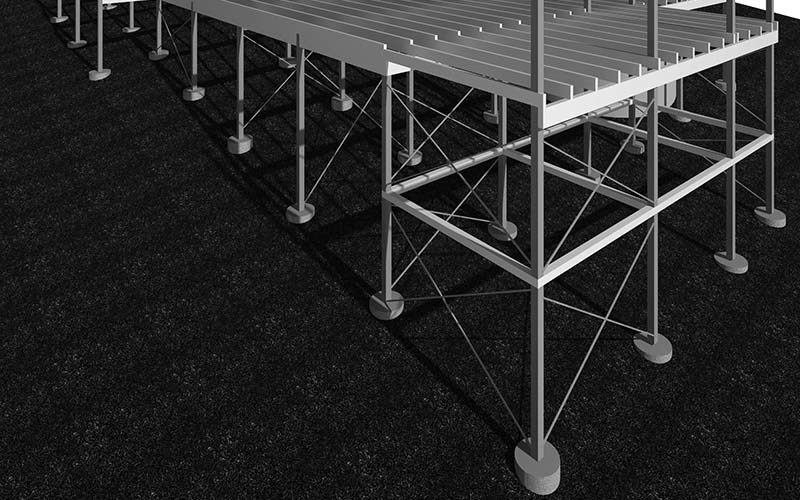

Step 6 - Bracing

If the floor system is significantly out of the ground, subfloor bracing may be required. This provides additional stability and support to the the floor system. Bracing usually comes in the form of a threaded rod which is fitted diagonally between two side by side posts. The threaded rod allows for tension to be applied once fitted.

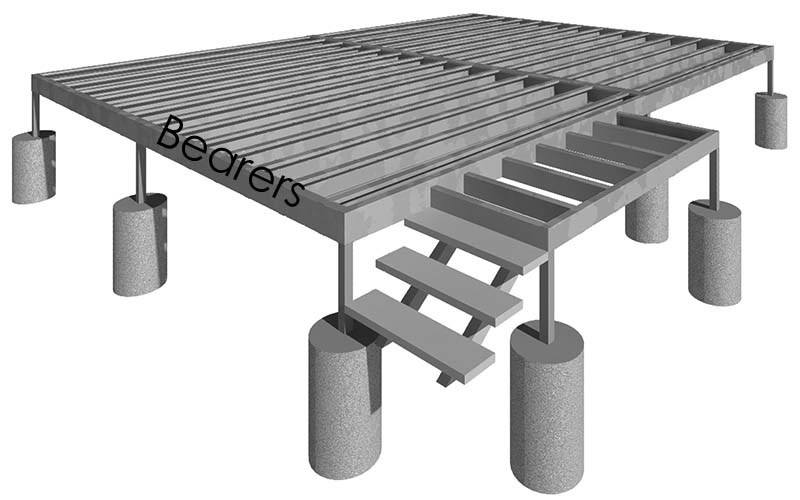

Step 7 - Bearers

Bearers for the floor system are available in a range of materials including: timber, laminated timber, steel C section or H beams. The bearers run length ways between the posts and carry the load of the building. The Shed House use a form of C section called nesting channel. The nesting channel is slightly larger than the C section allowing the joists to fit snug inside it.

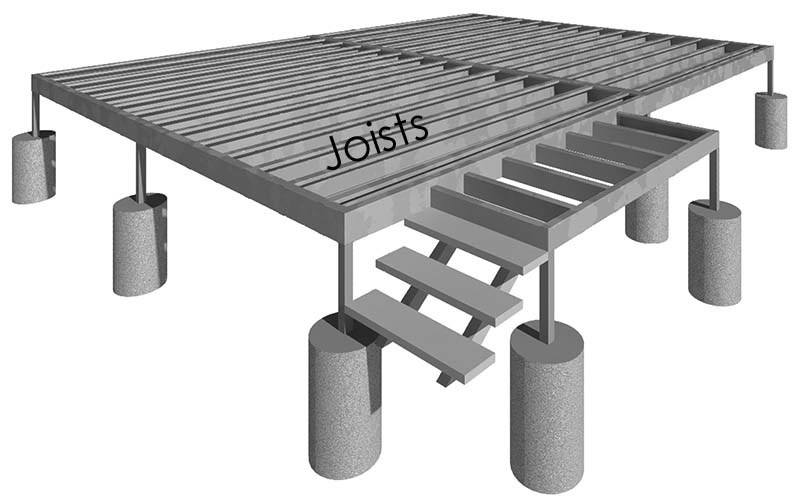

Step 8 - Joists

Joists come in a range of sizes and forms depending on span requirements and floor type. The Shed House do typically use C section joists which run inside the bearer and are secured using tek screws. This allows for quick construction times and a reduced number of posts.

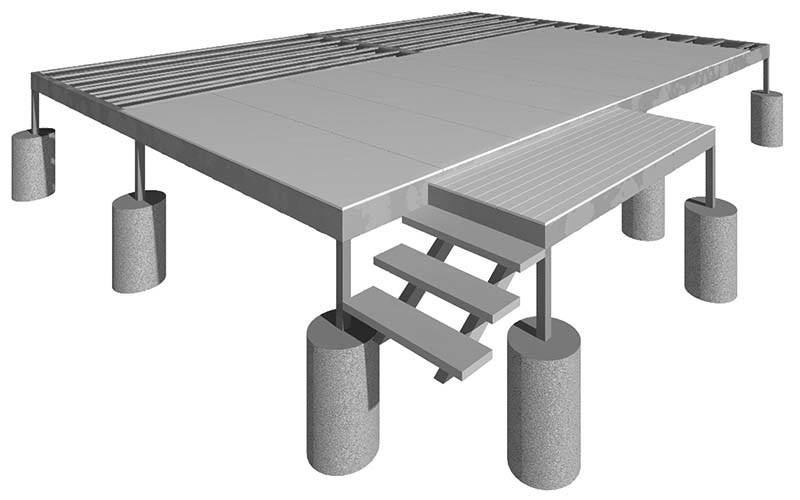

Step 9 - Flooring Material

Once your floor system has been built, we will provide a working and structural base for the building to sit on. The most common flooring options are: yellow tongue particle board, tongue and groove timber floor boards, hebel power floor and fibre cement sheet flooring. All have varied and different benefits. The Shed House typically uses yellow tongue flooring as it is cost effective and durable, therefore providing an economical and strong base for your building.